NanoTest Vantage:

Nanoindentation

The definition of nanoindentation is defined as an indentation performed on the nanometer length scale. More importantly, the depths to which the indenter is displaced into the surface is again within the nanometer scale. In order to accomplish this, your system must be capable of measuring the indentation depths with high accuracy. Therefore, nanoindentation can also be described as depth sensing indentation on the nanometer scale.

Specifications:

- 0.05 mN – 20 N load range

- 40 µm of depth capability

- Low thermal drift

- Accurate stage control (Res: 100 nm)

- Available fine stage control (Res: 10 nm)

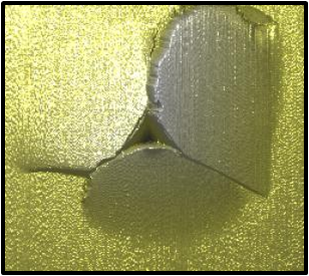

Scratch and Wear

The definition of nanoindentation is defined as an indentation performed on the nanometer length scale. More importantly, the depths to which the indenter is displaced into the surface is again within the nanometer scale. In order to accomplish this, your system must be capable of measuring the indentation depths with high accuracy. Therefore, nanoindentation can also be described as depth sensing indentation on the nanometer scale.

Advantages:

- The Scratch and Wear module allows for tribological testing with the NanoTest platform.

- Advantages:

- Available with the entire load range

- Highly reproducible

- Single and Multi-Pass

- Friction and Depth data

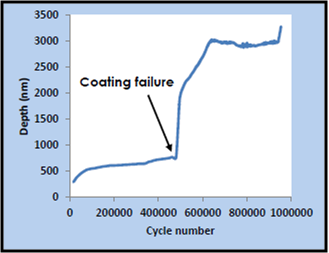

Nano Fretting

The Nano Fretting module allows advanced tribological testing of reciprocating wear on the micro/nano scale. This capability allows for the evaluation of small scale oscillatory motion on your samples.

- Fully programmable conditions

- High Cycle Wear

- Range of available indenters

- Geometries

- Materials

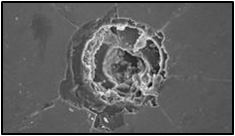

Nano Impact

The Nano Impact module will allow for high strain rate indentation. This is important to determine the toughness of a coating or material.

Advantages:

- Strain Rate Energy Densities into the ballistic range

- Single or Multiple Impact

- Accelerated Wear testing

- Frequency range: 1-500 Hz

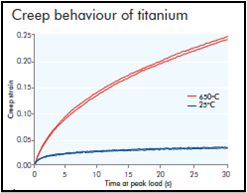

High Temperature

The capability to test your sample’s performance at the working temperature of your application can be crucial. Micro Materials, Ltd. has been the industry leader when it comes to high temperature nanomechanical testing.

Advantages:

- Thermal drift comparable to ambient

- Up to 750 °C

- Indenter and Sample heating

- Available with:

- Nanoindentation

- Scratch

- Impact

- High Resolution Imaging

Alternative Atmosphere

Micro Materials, Ltd. has been innovating the ability to test samples in their real world working conditions. The latest development has been in the area of alternative atmosphere testing and more specifically, high vacuum.

Options:

- Relative Humidity

- Purging Chamber for specific gases

- N2, Ar, CO2, etc.

- High Vacuum (10-6 torr)

Imaging Options

The imaging options from Micro Materials allow the user to locate desired regions for analysis, as well as to view the area after testing.

Available:

- 4-turret Optical Microscope Standard (5x, 10x, 20x, 40x)

- High Temperature Optics

- High Resolution Imaging

- Piezo Scanning Stage

- Dual or Single Mode AFM

For more information, click here.